Automatic 6 Nozzles Piston Filler

FP4300

lubricant oil filling machine

The Automatic 6 Nozzles Piston Filler FP4300 utilizes a linear conveyor, with a servo motor controlling the fast, precise, simultaneous filling of all six nozzles. For safety, the automatic bottle detection sensor stops the nozzles when an empty space is detected. The emergency stop button allows immediate ceasing of all operations if needed.

The 6 nozzles piston filling machine has a wide filling range, suitable for any particle-free and various low viscosity liquids on the market, including medicine, chemicals, oils, dairy, soy sauce, lotion, body wash, detergent, and other such free-flowing liquids.

The touchscreen HMI makes changing products quick and easy and reducing downtime between batches. When changing products, there are no parts that need to be replaced. It’s perfect for large-scale production because of its six nozzles, wide filling range, and precise filling levels. The stainless-steel frame guarantees resilience and ease of maintenance.

Advantages

1. Fills 12 ~ 30 bottles per minute (depending on liquid viscosity and container size)

2. Can fill all sizes and types of bottles

Application & Advantage

Suitable for

Water, soy sauce, essences, drinks, liquid face masks, shampoo, detergents, cleansers, perfume, essential oils, lotion, medication, eye drops, juice, alcohol, serums.

Suitable fields

Pharmaceuticals, food and drink, chemicals, cosmetics

- Features

1. High-class Japanese Mitsubishi servo motor for accurate and speedy production.

2. Filling speed, volume, and time interval can be set with the PLC control system’s color HMI touch panel.

3. Automatically saves filling parameters for future operation and setting.

4. Automatic bottle spacer and positioning system for continuous operation

5. Multiple filling modes for different liquids (above/below liquid surface or fixed-point filling).

6. Equipped with an emergency button and production warning system for safety concern.

7. Tricolor warning lights

8. Production detecting system prevents from bottle jam.

9. Any leaking problem can be immediately detected and corrected.

10. Ball-valve shut-off nozzle prevents liquid from dripping.

11. Made of anti-corrosion stainless steel that meet cGMP standards.

12. Suitable for different bottle shapes – round, oval, square, or flat-based bottles.

13. Stainless steel conveyor frame and bottle guider.

14. Filling tank sends material directly into bottles to reduce contamination.

15. Smart filling reduces filling errors when there are no bottles.

16. Diving filling nozzles prevent splashing and foaming.

17. Bottle separating system position bottles accurately.

18. Multiple-gear pump control simultaneous precise filling.

19. Closed filling system for safety and hygiene.

20. Numbers of gear pumps fill simultaneously to achieve high accuracy in high speed.

21. Equipped with spacer to make precise filling position.

22. Accumulated tray underneath nozzles.

23. Can be connected with production line or work independently.- Specification

- Filling Accuracy: ±0.5% ~ 1%

- Filling Volume: 50ml - 4000ml

- Power Supply Requirements: 110 or 220 VAC; 50Hz; Single phase

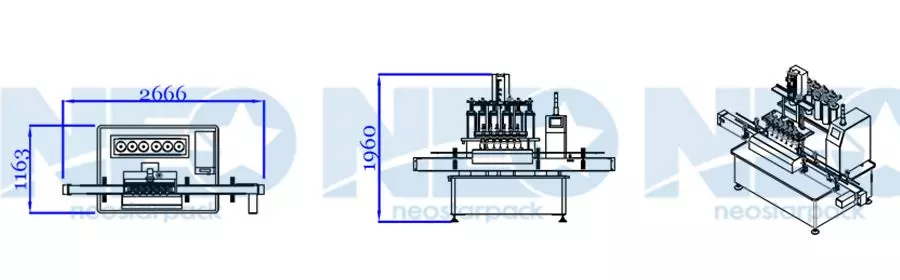

- Machine Dimensions: (L) 2666mm (W) 1663mm (H) 1960mm

- * Actual product specifications may vary.

- Option Accessories

- Protective casing

- Thermal transfer printer

- Infeed and outfeed turntables

- Filling modules (piston, peristaltic, etc.)

- Capper and labeler for full production line

- Feeding tray

- Customized stainless steel source hopper

- Introduce Movies

- Related Products

Automatic Piston Liquid Filler with Safety Cover

FP5300

FP5300 This volumetric piston filler is designed for general flowing liquids and liquids with...

DetailsAutomatic Piston Liquid Filling Machine

FP4150

Automatic two nozzles piston filler FP4150 is designed for general flowing liquids and liquids...

DetailsTwelve Nozzle Automatic Lubricant Oil Filling Machine (Piston Pump)

FP4670

Automatic 12 heads lubricant oil filling machine FP4670 works well with any free flowing liquid...

DetailsEnergy Saving Ration Liquid Filling Machine

FP2000

1. Suitable for medium viscosity liquid (such as lotion, oil and sauce) and liquid under 60 degree...

DetailsAutomatic Bottling Washer Filler Capper Line for Products of Viscous Liquids

NRT-100 / NBW-585 / NFP-540 / NCW-515 / NLR-300

Automatic bottling washer filler capper line integrates automatic bottle feeder, washer, filler,...

DetailsBottle Rinsing and Filling Machine Line

NBW-565+NFL-545+NCW-310

Bottle Rinsing and Filling Machine Line is built to help with product security and hygiene...

DetailsAutomatic 12-Nozzle Piston Filling Capping Labeling Line

NFP-4125+NCT-415+NLD-3055

Automatic12-Nozzle Piston Filling Line NFP-4125 connects a 12-nozzle piston filler with an automatic...

DetailsBig Volume Tabletop Piston Pump Liquid Filling Machine

FP1010

Big volume tabletop piston pump liquid filling machine FP1010 is designed for slightly thick...

DetailsTabletop Piston Pump Liquid Filling Machine

FP1005

Tabletop piston liquid filler fp1005 is available for products like cleanser, dishwashing liquid,...

DetailsTabletop Piston Filling Machine

FP1002

Tabletop piston filling machine FP1002 suits for small filling volume requirement, cylinder...

Details

Automatic 6 Nozzles Piston Filler - lubricant oil filling machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Automatic 6 Nozzles Piston Filler, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.