High Speed Automatic Capsule Counter

TC4200

capsules tablets pills counting machine,tablet capsule counting and filling machine

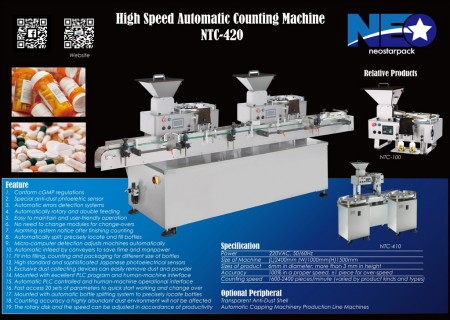

Straight feeding high speed automatic counting machines can calculate precisely tablets, capsules, pills, troches, dragées and chocolate, etc. in any types and sizes to fill them into many products. Automatic PLC controlled comprehensive location, bottle infeed, bottle splitting, counting and filling lead to efficient manpower. High speed automatic counting machines allow to have 20 sets of parameters for multiple counting productions at the same time.

High Efficiency High Speed Automatic Counting Machine

We adopt double-rail high speed automatic counting and double feeding counting machines, and the filling process works constantly and efficiently. The highly sophisticated electrical high speed automatic counting machines adjust and detect via computers, and the change-overs do not need to switch any components to save more time and enhance the productivity easily. For those products with big amount dust, we provide dust collecting devices to solve the problems. The independent CCD systems do not affect the accuracy of counting. The productivity of counting is up to 1600 to 2400 per minute in accordance of the size of products. The photoelectrical sensors can detect the counting errors and remove them. It is the primary choice of counting and packaging facility for many Chinese & Western pharmaceutical, biotech, healthy food, and OEM factories to manufacture efficiently.

- Features

1. Automatically splitting, precisely locate and fill bottles

2. Automatically rotary and double feeding connected with production line to enhance the productivity

3. Fast access 20 sets of parameters to quick start working and change over

4. Fit into different sizes and shapes of hard or soft capsules and tablets, no need to change modules for change-overs

5. Counting accuracy during production in a highly abundant dust environment will not be affected.

6. Automatic PLC controlled and human-machine operational interface allow convenient operation.

7. Special anti-dust CCD can be adjusted without affecting accuracy according to dust for products easily causing highly abundant dust.

8. Automatic errors detection systems remove the counting error and save the time of checking.

9. High standard and sophisticated Japanese photoelectrical sensors allow zero counting error.

10. Alarming system notice operators after finishing counting.

11. Fit into filling, counting and packaging in different size of bottles, easy to adjust.

12. Automatically locate, infeed, split up, feed, count and fill in the same production line

13. Flexibly choose to work with one or two machines according to the production needs

14. Mounted with automatic bottle splitting system to precisely locate bottles

15. Automatic infeed by conveyers to save time to convey and manpower

16. Exclusive dust collecting devices can easily remove dust and powder

17. Micro-computer detection adjusts machines automatically; easy to maintain and user-friendly operation

18. Mounted with excellent PLC program and human-machine interfaces to count quickly and fill stably.

19. The rotary table and the speed can be adjusted in accordance of productivity, and sizes in special diameters can be customized.

20. High speed automatic counting machines conform cGMP regulations, being solid, endurable and last with long life.- Specification

- Counting speed: 1600-2400 pieces/minute (varied by product kinds and tyeps)

- Sizes of products 6mm in diameter; more than 3 mm in height

- Accuracy: 100% in a proper speed, ±1 piece for over-speed

- Power: 220VAC, 50/60Hz

- Size of Machine: (L) 2400mm (W) 1000mm (H) 1500mm

- Option Accessories

- Transparent anti-dust shell

- Automatic capping machinery production line facility

- Photo Gallery

- Introduce Movies

- Related Products

High Accuracy Tablet / Capsule Counting Machine

TM4200

High accuracy tablet/capsule counting machine TM4200 suits for irregular shape and regular...

DetailsFixture Rotary Counting Machine

NTC-120

Fixture rotary counting machines are suitable for multiple products to count, fill, and pack....

DetailsTabletop Tablet Counting Machine (Capsule, Pill, Tablet Counter)

TC1000

Tabletop Tablet / Capsule Counter TC1000 is designed for high speed and precision quantitative...

DetailsTabletop Capsule and Tablet Counting Machine

TM1100

Tabletop vibrating double-rail capsule and tablet counting machines precisely count and fill...

DetailsAutomatic Counting Capping And Labeling Line

NTM-420+NCA-410+NLT-210

Automatic Counting Capping And Labeling Line is design for packaging regular counting materials,...

DetailsAutomatic Capsule Counting Filling and Labeling Line

NTC-410+NCW-310+NLR-300

Automatic Capsule Counting Filling And Labeling Line NTC-410 suits for counting various sizes...

DetailsProduction Line with Automatic Counting, Filling, and Capping Machines (Counting Machines, Power Filling Machines, Capping Machines, and Aluminum Foil Sealers)

NCT-410 / NCS-300 / NCW-310

The production line of pharmaceutical level equipment with automatic counting, filling, and capping...

Details- Files Download

High Speed Automatic Capsule Counter - capsules tablets pills counting machine,tablet capsule counting and filling machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include High Speed Automatic Capsule Counter, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.