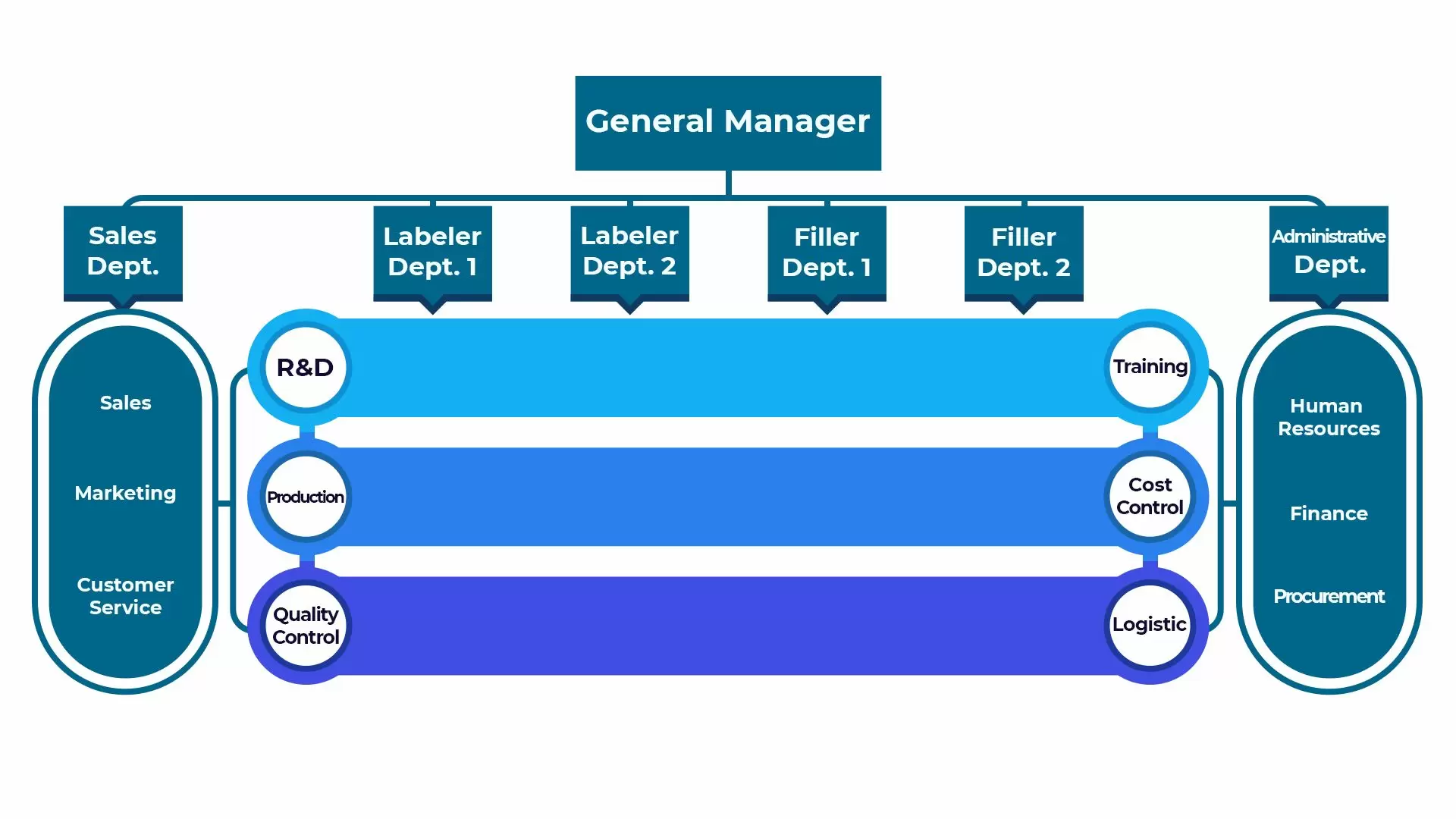

Company Structure

At the beginning of the establishment, Neostarpack started with labeling machines and continued to improve packaging machine expertise, expanding our product line to include liquid filling machines, tablet counting machines, capping machines, and other customized machines. In order to accomplish the business philosophy of full participation, the engineering team is divided into four groups: Labeler Group 1, Labeler Group 2, Filler Group 1, Filler Group 2. Each group has their R&D and manufacturing team members, able to provide the best solution to customers base on their needs. Our machines' sales volume and evaluation in the market are ahead of all others and have been recognized and recommended by many customers and partners. Neostarpack always adheres to rigorous requirements for quality, strengthens quality and service with teamwork, and creates professional customized planning for customers.

Department Features

1. Explore worldwide customers' needs of mid- and small-size bottle washing, filling, capping, and labeling machines, and promote Neostarpack's services: providing mid- and small-size bottle packaging line solutions to clients in the world.

2. Research the bottle packaging market trend and customers to access precise information anytime via decision making for the future and construct professional data system.

• Sales Department

Goal: The world's leading provider of 10-100BPM bottling solutions.

Sales Department is dedicated to

1. Explore domestic and foreign market needs and provide precise solutions to customer pain points.

2. Solve customers' problems and integrate machines for automated production planning.

3. Be aware of the company strengths and present them to customers.

With our expertise and experience, we have provided high-quality 10-100BPM bottling solutions to hundreds of customers around the world, and got unanimous praise and trust from customers.

• Management Department

Goal: As a solid logistics support for the team, provide a good working environment for all members.

Specialties

1. Taking long-term development as the concept, our human resources team provides adaptive development space.

2. Ensures transparency in information disclosure and fosters a corporate culture where all team members possess a business mindset, becoming a principled enterprise.

3. Provide manufacturing team with high-quality materials that meet international regulations and achieve prosperity with suppliers.

• Labeler Department 1

Goal: Create valuable products and keep improve the production process.

Main products: Round Bottle Labeling Machine, Top Labeling Machine, Side Labeling Machine.

Specialties

1. Proficient in the automatic labeling process for various products, and providing automatic labelers with precision, and efficient.

2. Automatic labeling machines adopt modular design, its production process is based on the TPS (Toyota Production System) to shorten the production cycle and build the best quality.

• Labeler Department 2

Goal: Providing outstanding electromechanical integration technology to create the best solutions for custom-built specialized machinery.

Main products: Double-Sided Labeling Machine, Bottle Rinser, Bottle Unscrambler, Custom-made Machine.

Specialties

1. Good at electromechanical integration and automated control. While complicated machines are operating, each mechanism can cooperate well to achieve accuracy and speed requirements.

2. Work with customers tightly to develop special machines that meet specific needs and face unprecedented technical challenges.

• Filler Department 1

Goal: Come up with the best solutions for customers.

Main products: Liquid Filling Machine, Powder Filling Machine, Screw-cap Capping Machine, Vial Crimping Machine, Vacuum Capping Machine.

Specialties

1. With years of experience, providing the best options based on customer’s products.

2. Develop user-friendly packaging machinery for operators based on ergonomics.

3. Integrate our diverse machines to provide high value-added bottling production line.

• Filler Department 2

Goal: Implementing valuable collaboration processes to create the correct value stream.

Main products: Multiple Channels Tablet Counter, Filling Machine, Compact Filling/Capping Line.

Specialties

1. Focus on the packaging needs in pharmaceutical industry and supplement industry, and provide high-efficiency advanced packaging machines.

2. With intelligent manufacturing as the core, integrate fillers and other packaging equipment to provide complete line planning that meets market demands.

3. Continuously advance the production process, maximize efficiency, and achieve high quality.