Automatic 8 Nozzles Gear Pump Liquid Filler

FG5400

Gear pump liquid filler,Bleach filling machine

Automatic 8 heads gear pump liquid filler FG5400 high speed lubricant filler is suitable for lubricant oil filling requirement with massive filling volume from 1 liter to 5 liter. Controlled by servo motor make filling precise and each nozzle can be adjusted individually. The 8-nozzle filling machine fills simultaneously with eight industrial-level nozzles for large-quantity production.

It's incredibly convenient to use, since it comes with a PLC control system with an HMI touch panel. The interface allows the operator to save up to 20 production parameters simultaneously, so that downtime is reduced between batches. Adjustments are simple - filling volume and speed can be changed via the touchscreen, and the nozzles can be positioned according to the size of the bottles. The frame of the machine itself is mounted on wheels so that it can be moved around.

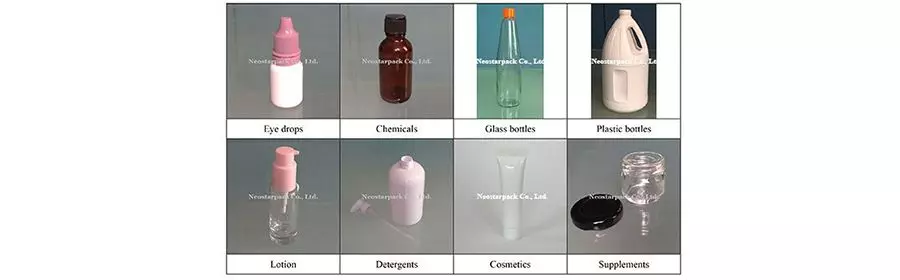

It's highly precise and can be used for all sorts of liquids such as engine oil, chemicals, drinks, liquid face masks, essences, essential oils, detergent, shampoo, cleanser, syrup, perfume, medication, eye drops, water, and more. It can be used with optional diving nozzles that reduce foaming, bubbling, and splashing, which often causes sanitary issues with food- and medical-grade products, and wastes product. The nozzles dive into the bottles, and follow the liquid as it rises, keeping the distance between the nozzle and water level at a minimum and thus ensuring smooth filling.

The automatic 8 heads liquid filling machine is made of SUS 304, 316 stainless steel and aluminum alloy, meeting cGMP level sanitary requirements. The conveyor belt is made of chained slats, which are easy to remove and clean. The machine is also equipped with several safety features, including an emergency stop button that pauses all operations, a production warning system that alerts operators of any abnormalities, and a safety cover for protecting the operators.

The 8 heads filling machine includes a 200L filling tank for large-scale filling, which can be replaced with a customized one if needed. The infeed and outfeed gates position bottles accurately, and a drip tray is positioned under the nozzles to catch any droplets. Automatic pneumatic shut-off nozzles are available, and are especially recommended for liquids that leak easily to enhance the anti-drip function. Furthermore, other optional add-ons are available, such as a capping machine, labeling machine, infeed turntable, or outfeed turntable. While the machine can be used on its own, connecting it with these other machines create a far more efficient automatic production line.

Advantages

1. Parameters can be adjusted using the touchscreen

2. The adjustments are easy to learn

3. Customizable design

4. Can be used in a full production line

5. Large-volume filling: 50 ~ 5000ml (can be customized)

6. Can fill all sizes and types of bottles

7. Filling precision within 0.5% ~ 1% margin of error

8. Suitable for free-flowing liquids under 6000cps

9. Fills 20 ~ 60 bottles per minute (depending on liquid viscosity and container size)

Application & Advantage

Suitable for

Low-viscosity liquids (below 40℃), such as drinks, liquid face masks, essences, essential oils, detergent, shampoo, cleanser, syrup, perfume, medication, eye drops, water, and engine oil.

Suitable containers

Plastic bottles, glass bottles, aluminum cans, metal cans.

Suitable fields

Pharmaceuticals, food and drink, chemicals, cosmetics.

- Features

1. Simultaneous filling with eight nozzles for high precision filling

2. Adopted lubricant oil pump for precise and smooth filling.

3. Servo motor controls each filling nozzle individually and accurate filling.

4. Pneumatic shut-off nozzle prevents liquid from dripping.

5. Pneumatic bottle positioning system and diving nozzle for precise filling.

6. Pneumatic drip tray with surplus oil backflow system.

7. Anti-bottle backup sensor ensures smooth transferring without jam.

8. Recipes for instantaneous changeover for different products can be stored as memory parameter.

9. Tank with product re-fill system and alarm for out of liquid.

10. Touchscreen to set filling volume, speed and interval time of each nozzle and shown filling status.

11. PLC control system with HMI touch panel for easy control.

12. Equipped with gear pump for liquids with different viscosities.

13.Special design reduces foaming and splashing.

14. Safety protective shield for operators’ safety

15. Equipped with production warning system

16. Equipped with gates for precise positioning

17. Fixed columns with wheeled frame, easy to move

18. 200L tank

19. Equipped with emergency stop button

20. Heavy duty and rigid construction: Made of SUS #304,316 stainless steel and aluminum alloy.- Specification

- Number of Nozzles: 8 Nozzles

- Automation Level:Fully automated

- Suitable Liquids:Free-flowing, under 40 degrees Celsius

- Filling Range:50~5000ml

- Filling Speed:50~250ml/sec

- Filling Precision:±0.5%~1%

- Suitable Containers :All types

- Power Supply:220 VAC, 50/60 Hz, 3 phase

- Machine Weight:500kg

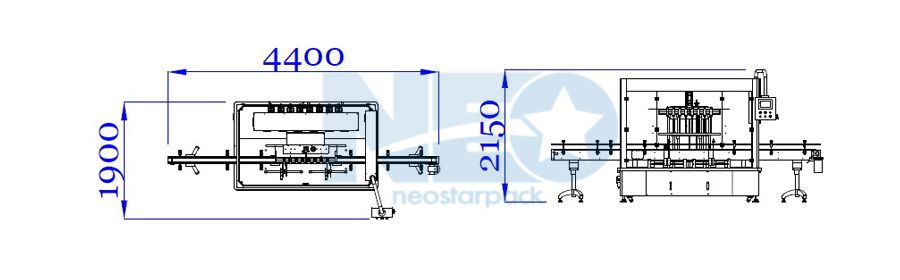

- Machine Dimension:(L)4400mm (W)1900mm (H)2150mm

- *Actual machine specifications may vary

- Option Accessories

- Infeed / Outfeed turntable.

- Anti-dust protecting case.

- Automatic pneumatic shut-off nozzle (Air required)

- Customized stainless steel source hopper

- PLC & HMI control system

- Diving nozzles

- Photo Gallery

- Introduce Movies

- Related Products

Automatic Gear Pump Liquid Filler

FG4250

FG4250 suits for various low viscosity liquid, such as lotion, syrup, cleanser, etc. No adjustment...

DetailsAutomatic Bottle Filling Machine

FG5650

Automatic bottle filling machine having 12 head automatic liquid filling machine, filling machine...

DetailsFully Automated Filling-Capping-Labeling Production Line

FG5470-CS4150-LD4000

The system is widely used in food and beverage plants, pharmaceutical plants, plants of body-care...

DetailsAutomatic Bottle Rinsing Filling and Capping Machine

NBW-565 / FG-585 / NCW-310

Fully Auto Bottle Rinsing Filling and Capping Machine This is touch screen PLC base Rotary...

Details

Automatic 8 Nozzles Gear Pump Liquid Filler - Gear pump liquid filler,Bleach filling machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Automatic 8 Nozzles Gear Pump Liquid Filler, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.