High-speed Spindle capping machine

CCS3000

High-speed Spindle capping machine

The High-speed Spindle capping machine CCS3000 is a high speed capping machine, and can be used for any kind of caps, such as screw caps, plastic round bottle caps, spray bottle caps, pump caps, metal caps, flip-top caps and more. The universal grippers are able to handle any of these caps with the proper torque and stable capping force, while the capping time and height are adjustable to optimize capping. Capping speed can reach up to 100 bottles per minute.

The CCS3000 is programmed with a PLC system, and uses a colored HMI touchscreen. The capping machine also has waterproof sensors and meets both cGMP standards. It can easily be connected to other machines in a production line, and is designed for quick changeover between products, with automatic operation and controls. It's easy to catch any issues with the tri-color light warning system, and the bottle jam detection sensor. The capping counter also keeps track of production so any problems can be found quickly.

The Spindle capping machine CC3000 is highly customizable, with a large number of available add-ons. The conveyor's width can be customized, and the capper can be paired with an optional cap feeding device or cap reloader. There are infeed and outfeed turntables available to feed and collect product, and a filler and labeler can be added to create a full production line. A bottle rejector can also be added to remove any bottles that do not meet production standards. To learn more about which product and add-ons would be ideal for a particular product, contact Neostarpack for a free consultation.

Advantages

1. Universal grippers, suitable for any cap

2. Adjustable capping time and height provides high capping flexibility

3. Automatic operation and control complies with cGMP standard

4. Can be used as part of a production line

5. Motor-controlled cappers for stability and strength

Application & Advantage

Suitable Industries

Pharmaceutical, cosmetics, chemical, food and drink.

Suitable Caps

General plastic caps, PET caps, downward pressing caps, safe pump heads, duckbill caps, and screw caps.

Capping Method

Screw-on

Capping Speed

50~100 BPM

Applicable cap diameter

20-55mm

- Features

-

1. Can be used for: general plastic caps, PET caps, downward pressing caps, safe pump heads, duckbill caps, and screw caps

2. Rubber capping wheels protect caps and ensure firm gripping

3. Precise high torque design for high capping quality with proper tightness to prevent over-capping

4. Driven by adjustable AC motor

5. Linear capping process, perfect for linking up with other machines

6. Easy to use; long-lasting with proper maintenance

7. Customizable conveyor width

8. Multiple adjustment modules, with both manual and automatic adjustments for capping height

9. Control panel includes production parameters, which can be saved and used as needed to save line changing time

10. Safety devices to prevent improper operating and protect workers

11. Made of SUS#304 stainless steel and aluminum for easy maintenance and cleaning

12. Programmed with PLC

13. User-friendly HMI color touchscreen, with simple maintenance instructions

14. Capping output counter to track production levels

15. Emergency stop button

16. Three-color warning light

17. IP65 machine shell which offer complete protection against particles, and a good level of protection against water.

18. Can be moved as needed, mobile and ready to work anywhere

19. Bottle jam detection sensor and alarm, with automatic machine stopping

20. Can be used for a full line (bottle washing→filling→capping→labeling) - Specification

-

Applicable cap type: Screw caps / Pump / Spray / Mushroom-Shaped Cap

Capping Speed: 50~100 BPM

Applicable cap diameter: 20-55mm

Bottle type: Round bottle, Square bottle

Bottle applicable: Bottle height: 50 ~ 150 mm / Bottle diameter:30 ~ 100 mm

Capping speed: 50~100 bottles / min

Power supply: 110 or 220VAC, 50/60Hz , single phase

Air Requirement: 2~6 kg/cm2

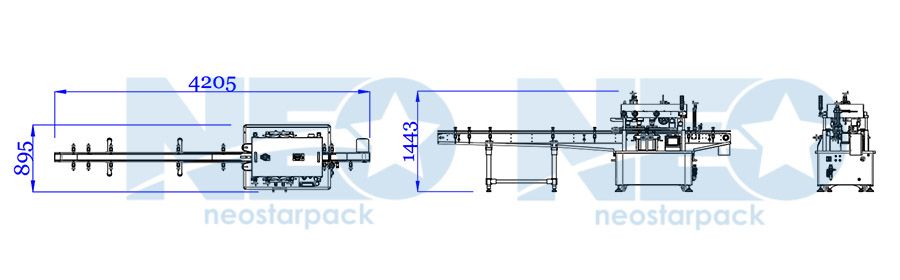

Machine Dimensions: (L) 4200mm (W) 900mm (H) 1450mm

* Actual product specifications may vary - Option Accessories

-

- Automatic cap feeding device

- Waterfall type cap reloader

- Bottle rejector

- Safety cabinet – shuts down when doors open

- Infeed turntable

- Bottle conveyor module

- Introduce Movies

- Related Products

-

Automatic Indexing Spindle Capping Machine

CS3000

Automatic indexing spindle capping machine uses the universal gripper to cap with proper torque,...

DetailsAutomatic Dual Servo Motor Capper

NCW-415S

NCW-415S Automatic Dual Servo Motor Capper can be easily adjusted with the capping head to meet...

DetailsAutomatic Capper

CC4170

Automatic Capper CC4170 can be easily adjusted with the capping head to meet different capping...

DetailsAutomatic Bottling Washer Filler Capper Line for Products of Viscous Liquids

NRT-100 / NBW-585 / NFP-540 / NCW-515 / NLR-300

Automatic bottling washer filler capper line integrates automatic bottle feeder, washer, filler,...

DetailsProduction Line with Automatic Counting, Filling, and Capping Machines (Counting Machines, Power Filling Machines, Capping Machines, and Aluminum Foil Sealers)

NCT-410 / NCS-300 / NCW-310

The production line of pharmaceutical level equipment with automatic counting, filling, and capping...

DetailsFully Automated Filling-Capping-Labeling Production Line

FG5470-CS4150-LD4000

The system is widely used in food and beverage plants, pharmaceutical plants, plants of body-care...

DetailsAutomatic Bottle Capping Machine

CS4150

Automatic bottle capping machine CS4150 integrates cap feeding, cap placing and capping functions...

DetailsTabletop Screw Capping Machine

CS1000

This tabletop screw capping machine can do capping on a various kind of screw caps such as plastic...

DetailsBottle Rinsing and Filling Machine Line

NBW-565+NFL-545+NCW-310

Bottle Rinsing and Filling Machine Line is built to help with product security and hygiene...

DetailsAutomatic 12-Nozzle Piston Filling Capping Labeling Line

NFP-4125+NCT-415+NLD-3055

Automatic12-Nozzle Piston Filling Line NFP-4125 connects a 12-nozzle piston filler with an automatic...

DetailsAutomatic Capsule Counting Filling and Labeling Line

NTC-410+NCW-310+NLR-300

Automatic Capsule Counting Filling And Labeling Line NTC-410 suits for counting various sizes...

Details

High-speed Spindle capping machine - High-speed Spindle capping machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include High-speed Spindle capping machine, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.