Tabletop Screw Capping Machine

CS1000

semi automatic screw capper, bottle capper machine,plastic spray bottles capping machine

This tabletop screw capping machine can do capping on a various kind of screw caps such as plastic round bottle cap, aluminum cap, spray bottle cap, duckbill bottle cap, iron caps, and can easily apply to many different industries unlimited. Tabletop screw capping machine has new mechanism integration design that has much more compact machine frame and less space is needed comparing to tabletop semi-automatic capping machine CS1000.

By Integrating all control and operation system in one interface, the machine operator can do capping in lesser space and shorter period of time. Because the torque motor control system remains capping consistency in the long run, you don’t need to worry about it.

Tabletop Screw Capping Machine That Can Use On A Various Of Caps Provide High Cost-Performance Ratio

Tabletop screw capper CS1000 is simple to set-up and easy to operate, and its torque motor control capping tightness that can meet requirements for different industries. This semi-automatic capping machine has advantage on its widely use range, and you don’t need to change the capping head because of different cap size/height. Also, the solid construction of the machine means less spare parts are needed in the future.

Advantages

1. Cap various round bottles with one machine.

2. Rubber wheel protect your cap and container.

3. Microcomputer control panel to adjust parameters is easy to use.

4. Product replacement is simple and fast.

5. Suitable for small space operation.

Application & Advantage

Suitable for

Products with screw-on caps such as edible oil, sauces, wine bottles, medicine bottles, tea cans, lotions, shampoos, detergents, perfumes, lipsticks, lip gloss, plastic bottles, glass bottles, aluminum cans, iron cans, etc.

Suitable Caps

Screw-on caps such as plastic round bottle caps, aluminum caps, spray bottle caps, duckbill bottle caps, iron caps, tamper-proof caps, child-safe caps.

Capping style

Screw-on capping.

- Features

1. compact design suitable for limited space and easy to be moved to anywhere.

2. it’s adjustable according to the bottle height, being able to apply to multiple product types.

3. The torque motor control system remains capping consistency in the long run.

4. There is no need to change the capping head for different cap sizes, easy product changeover.

5. The machine is equipped with hand wheel for tool-free height adjustment.

6. Capping mode: can switch between auto/ semi-auto (pedal)mode depending on your capacity.

7. Single capping machine can meet the requirements for both small scale and mass production.

8. All capping heads have buffering material for caps protection.

9. Built to last: all machine was made of stainless steel and harden aluminum alloy.

10. The screw capping torque can be adjusted easily for appropriate tightness.

11. High standard stainless cover shell protects the machine from ash and dust, making it easy to clean.

12. Environmental friendly design and less supply needed.

13. All mechanisms are close to operator’s working area, improving work efficiency.

14. it’s simple to operate because there is no complicate program setting.

15. Can apply to any screw caps for plastic bottle, wine, metal bottle and so on.

16. Fast changeovers between bottles or caps.- Specification

Bottle types: HDPE、PET、LDPE and glass bottle.

Cap types: All screw caps

Caps outer dimension: 20-110 mm

Capping speed: 15-30 bottle per min

Air pressure requirement: 2-5Kg

Power supply: 110V or 220VAC, 50/60Hz

Weight:20 kg

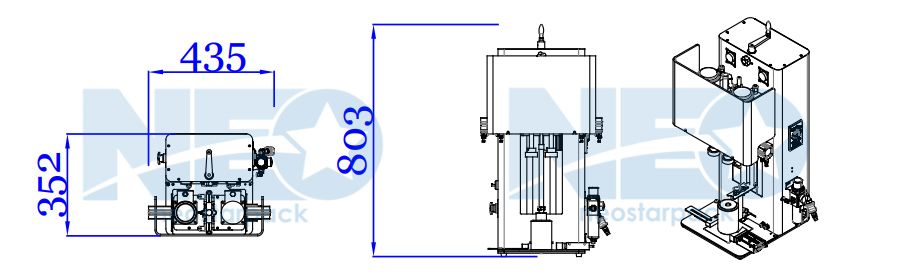

Machine Size (L)352mm x (W)446mm x (H)803mm

- Option Accessories

- Customized capping head

- Spare parts: rubber wheel

- Table kart

- Photo Gallery

- Introduce Movies

- Related Products

Tabletop Semi-automatic Capping Machine

NCW-100

The light and sophisticated tabletop semi-automatic capping machine is able to be placed in a workplace...

DetailsAutomatic Bottle Capping Machine

CS4150

Automatic bottle capping machine CS4150 integrates cap feeding, cap placing and capping functions...

DetailsAutomatic Dual Servo Motor Capper

NCW-415S

NCW-415S Automatic Dual Servo Motor Capper can be easily adjusted with the capping head to meet...

DetailsAutomatic Indexing Spindle Capping Machine

CS3000

Automatic indexing spindle capping machine uses the universal gripper to cap with proper torque,...

DetailsCompact Filling Line (Filler / Capper / Labeler)

Semi-automatic star wheel capper is the best solution of automatic filling line for flexible...

DetailsAutomatic Bottling Washer Filler Capper Line for Products of Viscous Liquids

NRT-100 / NBW-585 / NFP-540 / NCW-515 / NLR-300

Automatic bottling washer filler capper line integrates automatic bottle feeder, washer, filler,...

DetailsProduction Line with Automatic Counting, Filling, and Capping Machines (Counting Machines, Power Filling Machines, Capping Machines, and Aluminum Foil Sealers)

NCT-410 / NCS-300 / NCW-310

The production line of pharmaceutical level equipment with automatic counting, filling, and capping...

DetailsCounting Filling Capping labeling Line

NTC-410

Counting Filling Capping labeling Line NTC-410 suits for counting various sizes of products...

DetailsTablet Counting Filling Line

NTC-420

Tablet Counting Line NTC-420 is design for packaging regular counting materials, such as tablet,...

DetailsBottle Rinsing and Filling Machine Line

NBW-565+NFL-545+NCW-310

Bottle Rinsing and Filling Machine Line is built to help with product security and hygiene...

DetailsAutomatic Bottle Rinsing Filling and Capping Machine

NBW-565 / FG-585 / NCW-310

Fully Auto Bottle Rinsing Filling and Capping Machine This is touch screen PLC base Rotary...

DetailsAutomatic Capsule Counting Filling and Labeling Line

NTC-410+NCW-310+NLR-300

Automatic Capsule Counting Filling And Labeling Line NTC-410 suits for counting various sizes...

Details

Tabletop Screw Capping Machine - semi automatic screw capper, bottle capper machine,plastic spray bottles capping machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Tabletop Screw Capping Machine, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.