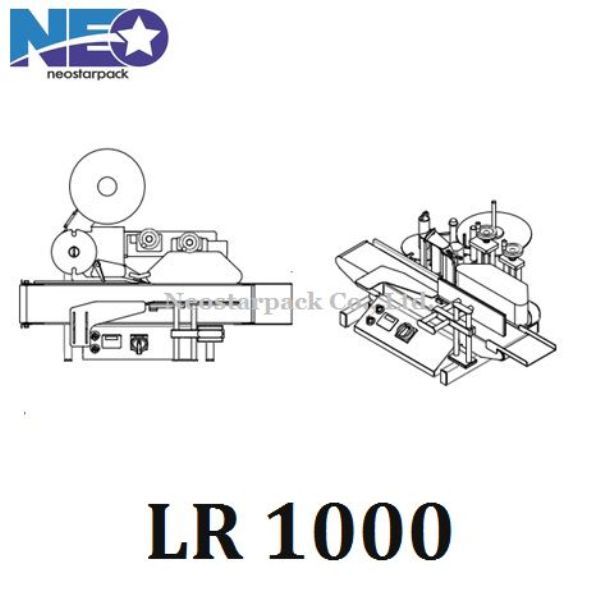

Tabletop Round Bottle Labeling Machine

LR1000

Sami-auto round bottle labeling,machine,glass bottle labeller,nutritional supplement labeller

Tabletop round bottle labeling machine LR1000 is very suitable for small and medium manufacture who want to improve the quality of packaging. Round bottle labeler is controlled by a micro-computer, this labeling machine can complete high-precision labeling that is difficult to complete by manual work.

The labeling is consistent, horizontal and very beautiful. LR1000 series round bottle labeller is recommended to clients with limited production space. The length of the machine is about the length of an adult's arm, so it can be used in a small space for semi-automatic production. Its space-efficient size makes it the best bottling solution for small or medium-sized business expecting moderate but versatile labeling needs. Tabletop round bottle labeling machine can be combined with an Ink jet printer / Date coder to satisfy your further production needs.

Tabletop Round Bottle Labeller Advantage

1. Microcomputer control panel to adjust parameters, easy to use.

2. Label replacement is simple and fast.

3. Driven by stepper motor, quiet and smooth.

4. Suitable for small space operation.

5. Comply with cGMP.

6. It is applicable to extensive range of products in different industries.

Application & Advantage

Speed Adjustment-Free Smart Round Bottle Labeller

This round bottle labeling machine is an economical model and is recommended for small and medium producers who have a small amount and diversification and pursue high-quality. Simple operation and high supportability. Equipped with a smart photo-electronic eye, it automatically applies labels to round bottles with only two buttons pushed. Such automatic feature frees you from complicated parameter settings and speed adjustments; and thus avoiding setting errors. The conveyor speed and labeling head position can be flexibly adjusted according to your production needs and the bottle size. It is applicable to a wide range of industries: The food, medicine, biotechnology, and chemical industries can use this labeler to achieve stable labeling quality. This round bottle labeler equipment worthy of your investment.

Tabletop round bottle labeler suitable for

Cylindrical products such as edible oil, sauces, wine bottles, medicine bottles, tea cans, lotions, shampoos, detergents, perfumes, lipsticks, lip gloss, plastic bottles, glass bottles, aluminum cans, iron cans, etc.

Label

Self-adhesive labels, anti-counterfeit labels, promotional labels, tamper-evident labels, tube labels, vial labels, lab labels, transparent labels (work with photoelectric sensor for transparent labels).

Labeling style

wrap-around labels, half wrap bottle label, single-side labels.

- Features

1. Adjustable labeling height and angel through PLC program; no manual adjustment needed.

2. User-friendly control system makes the operation easy and fast.

3. Equipped with finely-made Japanese photo-electronic eye; detecting targeted labeling position with great accuracy.

4. Powered by step motors; producing stable and efficient labeling outputs.

5. Modularized machine parts: Satisfying your different labeling needs by different modules.

6. Setting Label length through PLC system; changing products with ease.

7. Streamlined conveyor belt moves extensive range of products; Switching labeling products with ease and efficiency. Space-efficient size: great for limited work space.

8. Equipped with a label-pressing sponge; firmly applying labels to your applications.

9. Mico-computer controlled PLC system meets production goals with efficiency.

10. Sychronized labeling speed and conveyor speed; making speed adjustment fast and easy.

11. Labeling roll firmly attaches labels to your products.

12. Equipped with automatically-detecting photoelectric eyes, round bottle labeling machine NLR-100 makes it easy to change labels and labeling products at the same time. No further adjustment is needed.

13. Made of stainless steels and hardened aluminum alloy; providing great solidity and durability.

14. Easy for maintenance and clean up.

15. Comes with rigorous quality check and comprehensive customer support.

16. Labeling speed varies depending on the size of your labels and that of your products.

17. Customizable machine parts; extendable range of applicable products.

18. Equipped with adjustable conveyor fences and hand wheel system; providing excellent control experience.- Specification

- Powered by stepper motors

- Labeling Speed: 20-60 pcs/min (depending on your specific applications and label sizes)

- Labeling accuracy: ± 1 mm (depends on product and label size)

- Bottle size: diameter 16mm-90mm/ height 30-160 mm

- Applicable Label Width/Length: 10-100mm/ 20-300mm

- Labeling Roll Diameter: Inside 75mm; Outside 300mm

- Power Input: 110/220 VAC; 50/60 Hz

- Dimensions: (L) 1234mm (W) 839mm (H) 540mm

- Option Accessories

- Tamp fixed point roll-labeling sets: applicable for the labeling of 3/4 to whole wraparound bottle body; with great precision.

- photoelectric sensor for transparent labels.

- Date coding machine/ Ink jet printer

- Automatic feeding machine

- Introduce Movies

- Related Products

Tabletop Bottle Labeling Machine (Standard Model)

LR110A

Our tabletop round bottle labeler can make all kinds of round bottle labeling job done with...

DetailsTabletop fully wrap around labeler

LR117A

The Tabletop round bottle labeling machine LR117A is able to position the bottles in exact...

DetailsTabletop Automatic Top Labeler

LT1000

The Tabletop automatic top labeler LT1000 is an economic, budget friendly piece of machinery...

DetailsTabletop Top Labeler

LT1100

Our LT1100, tabletop top labeler works with high efficiency, while provides perfect labeling...

DetailsTabletop Tamp Labeler

LS1000

LS1000 Tabletop tamp labeler is powered by step motors, which produce stable labeling outputs....

DetailsCompact Filling Line (Filler / Capper / Labeler)

Semi-automatic star wheel capper is the best solution of automatic filling line for flexible...

DetailsTop Tamp Labeler (Top Tamp Labeling Machine)

LS1200

Top tamp labelers LS1200 is space-efficient. Each part of it comes in high standard. Its high...

Details

Tabletop Round Bottle Labeling Machine - Sami-auto round bottle labeling,machine,glass bottle labeller,nutritional supplement labeller | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Tabletop Round Bottle Labeling Machine, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.