Vacuum Capping Machine

CCV2000

Vacuum Capper, Glass Jar Vacuum Capper, Twist off cap vacuum capping machine

Vacuum capping machine is a packaging machine designed for the sealing of twist off caps. It is mainly used to remove the air in the container to create a vacuum seal state, while capping the container, such as a glass bottle or a glass jar. This vacuum capping process keeps the container sealed tightly, allowing the product inside to maintain its freshness longer. Vacuum sealing can prevent the growth of bacteria and other microorganisms, help to avoid spoilage and extend the expiration date of the product at the same time.

To operate vacuum capper CCV2000 is as easy as to put a bottle into the mold of the machine, then press the start button. After capping process starts, the mold will rise and combine with the sealing ring to a hermetic state (vacuum chamber). Vacuum pump removes the air in the bottle to create negative pressure inside, in the meanwhile, put the cap on and keep the vacuum state. The capping head then tighten the cap under the vacuum state, reach required vacuum degree. After the mold is back to its original position, you can take out the finished product. The whole process only takes a few seconds to complete, vacuuming and capping at the same time.

The common twist off cap of glass bottle on the market, its center will be concave after vacuum capping. Therefore, consumers are able to recognize the completeness and safety of packaging by the cap. CCV2000 is commonly used in the food and beverage industry, pharmaceuticals and cosmetics industry, where the freshness and quality of products are crucial factors.

Torque motor and pressure adjust system ensure product quality

Glass jar vacuum capper CCV2000 equips with torque control function, which keeps the capping tightness consistent. The capping torque can be set on the touchscreen to maintain consistent vacuum pressure, and to ensure the sealing tightness of the product while not damage the cap. In addition, the vacuum pressure is adjustable to fit different container and cap sizes. Precisely sealing in highly efficient, saving time and labor cost, during the packaging production process.

Customized and quick-change modules speed up product changeover time

The bottle mold of the vacuum capping machine is customized according to the size of the bottle to make sure the best vacuum capping performance. Simply add additional bottle molds, if there are various sizes of glass bottles.

Twist off cap vacuum capping machine CCV2000 is designed for small amount/batch of diversified productions. Its high-quality quick-change bottle mold is convenient for changeover between products, and the downtime is short. Vacuum capper is a high-value packaging machine for many products that require high-quality, sealing packaging, providing the advantages of maintaining product freshness, preventing spoilage, maintaining product flavor and extending the expiration.

Advantages:

- Suitable for glass bottle or glass jar packaging with twist off caps.

- Meet the vacuum requirements of food deoxygenation packaging.

- Durability and reliability: It’s made of high-quality materials and easy to maintain.

- Suitable for different sizes of cap.

- Fast and efficient sealing caps: Sealing the container correctly.

- Extend the expiration date: Vacuum sealing can avoid spoilage and extend the expiration date of the product.

Application & Advantage

Suitable goods

Meat, dairy products, soy products, seafood, spicy sauce, ketchup, jam, honey, yogurt, picked food, canned vegetables (spicy radish, chickpea), Mayonnaise, sauces, Bolognese Sauce (spaghetti sauce), caviar, mayonnaise, seasoning sauce, spread, beverages, nutritional supplement, pharmaceuticals, cosmetics, facial creams, serums, chemical reagent, biologic therapy, solvents, adhesives and other compounds, seeds, fertilizers, and agricultural products.

Suitable container

Usually used for a variety of different shapes and sizes of glass bottles with twist off caps; round bottle, square bottle, long neck bottle, short neck bottle, wide mouth bottle, straight mouth glass bottle. (Different vacuum cappers get different limits to container size and shape. Before purchasing, it is necessary to confirm whether it is suitable for your container according to the size of the capping head and its components.)

Capping style

Torque capping. (Torque capping is to rotate the caps ‘til the set torque and screw tightly.)

Suitable industries

Food and beverage industry, pharmaceutical industry, biotechnology industry, cosmetics industry, chemical industry, agricultural industry.

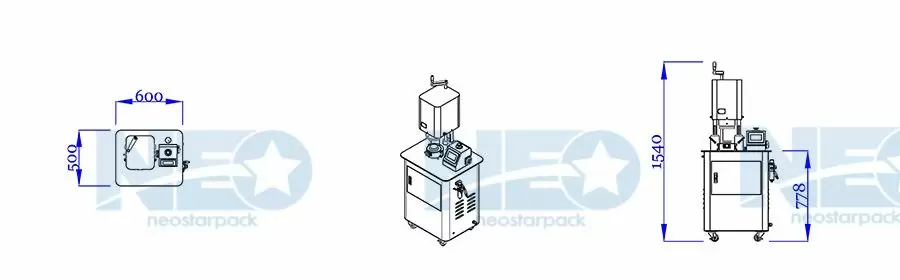

Machine layout

- Features

1. Adjustable vacuum pressure: The capper gets an adjustable vacuum pressure setting to cope with different requirements and different types of containers.

2. High quality sealing: Excellent sealing components provide reliability to ensure product safety.

3. Easy to utilize and clean:

Easy to use with direct control system.

Easy to clean and maintenance with removable parts for cleaning and disinfection.

4. Save time and labor cost: It takes only a few seconds to remove air and capping, helping the clients to reduce the labor cost in production.

5. Consistency:Capper CCV2000 maintains consistent vacuum pressure during the capping process to ensure that all bottle containers are completely sealed to prevent leakage or spoilage.

6. Versatility:The capper is suitable for various sizes and shapes of glass containers. It also can be equipped with different sizes of components to adapt to diverse caps, becoming a multi-functional packaging solution.

7. Efficient & precise:Fast and efficient sealing cap

8. User-friendly touch interface: Visual control touchscreen makes operation easier.

9. The size of CCV2000 is equivalent to a water dispenser. It's suitable for companies with limited spaces.

10. It provides reliable deoxygenation sealing for glass containers to make sure product quality and prevent spoilage.

11. Customized bottle molds to ensure the best vacuum quality

12. Safe operation with emergency stop button.

13. The capper is shipped with foot pedal for easier activation.

14. Made of SUS#304 stainless steel and aluminum alloy; firm and durable

15. Optional bottle molds: Changeover the bottle molds can produce more sizes of products.

16. It can be integrated into our existing filler and labeler to build a semi-auto packaging production line.

17. A simple hand-wheel to adjust the capping height

18. The time and torque of capping can be set by touchscreen.- Specification

Automation Level

Semi-automatic

Capping Speed

5~15 bottles/min (depends on operators)

Cap Diameter

ø40-100mm, single size mold

Bottle Diameter

ø40-100mm, single size mold

Bottle Height

50-180mm

Vacuum Degree

740mmHg(98.66KPa)

Vacuum Pump Consumption

100L/min(60Hz), 85L/min(50Hz)

Power Requirement

110 or 220VAC, 50/60Hz, Single phase

Air Supply

4~6kg

Machine Size

(L)600mm (W)500mm (H)1540mm

* Actual product specifications may vary

- Option Accessories

- Customized Bottle Mold

- Introduce Movies

- Related Products

Semi-Automatic aluminum Screw Capping machine (ROPP Capper)

CR1000

Semi-Automatic Aluminum Screw Capping Machine CR1000 is suitable for products sealed with spiral...

DetailsAutomatic Aluminum ROPP Capping Machine

CR4000

The automatic aluminum ROPP capping machine uses the automatic aluminum cap feeding and capping...

DetailsAutomatic Vial Crimper

CV3000

The automatic vial crimper adopts rotary disk to close bottle aluminum caps. Vial crimper can shorten...

DetailsTabletop Vial Crimping Machine

CV1000

Tabletop vial crimping machine CV1000, also called vial aluminum cap capping machine, is a small-size...

DetailsAutomatic Indexing Spindle Capping Machine

CS3000

Automatic indexing spindle capping machine uses the universal gripper to cap with proper torque,...

DetailsAutomatic Dual Servo Motor Capper

NCW-415S

NCW-415S Automatic Dual Servo Motor Capper can be easily adjusted with the capping head to meet...

DetailsAutomatic Counting Capping And Labeling Line

NTM-420+NCA-410+NLT-210

Automatic Counting Capping And Labeling Line is design for packaging regular counting materials,...

Details

Vacuum Capping Machine - Vacuum Capper, Glass Jar Vacuum Capper, Twist off cap vacuum capping machine | Sold in 50 Countries High-Quality Industrial Packaging Equipment Manufacturer | Neostarpack Co., Ltd.

Based in Taiwan since 1998, Neostarpack Co., Ltd. has been an industrial packaging machine manufacturer. Our main products, include Vacuum Capping Machine, labelers, liqiud filling machines, tablet counters, capping machines, bottle rinser machines, complete filling lines, label counters, card feeders and label dispensers, which are total packaging solutions for customers in bottling packaging machinery industry.

Neostarpack team has devoted ourselves to manufacture labeling machine, automatic filling machine, tablet capsul counter, capping machine, and other packaging machine. We offer bottle packaging solutions, help to improve production automation experience for over 20 years. We also provide professional OEM service and customized machine. We extend business domain to over than 50 countries.

As an automatic filling packaging line supplier, besides packaging labeling and capping equipment, filling and closing machine can be tailored to the specific needs of the customers and their industries. Both with advanced technology and 25 years of experience, Neostarpack ensures each customer's demands are met.